The History of the Transit Mixer in Australia

This month we continue the story of the Concrete Transit Mixer in Australia.

The year 1948 saw both R.M.C. limited and Certified Concrete import a serious number of “Rex” mixers from the Rex Chain Belt Company of Milwaukee, U.S.A. These units were the first inclined axis models built in the world.

Rex having introduced the idea back in 1941 with the main object of obtaining a high discharge point in com-parison to the horizontal mixers which discharged at a lower level.

The Rex machines were fitted with a hinged door over the mouth of the drum, which incorporated the charging chute. The machine was charged in the usual way with the drum rotating in the for-ward direction. As soon as all the materials were charged, the drum would be reversed with the mouth door closed – the material thereby falling to the lower end of the drum.

Discharge was achieved fairly primitively by way of opening the door and the concrete flowing onto the discharge chutes.

The Rex Mixer was well built, but very expensive. Generally, they were mounted on Ford Thornton & G.M.C. 6 x 6 trucks. An alternative to the expense was found with a virtual copy of the Rex ma-chine being made in Australia by Transport Equipment Co. This machine had a hinged door at the drum mouth and was powered by a Universal 4-cylinder engine driving through a gearbox to a spur gear drive on the drum.

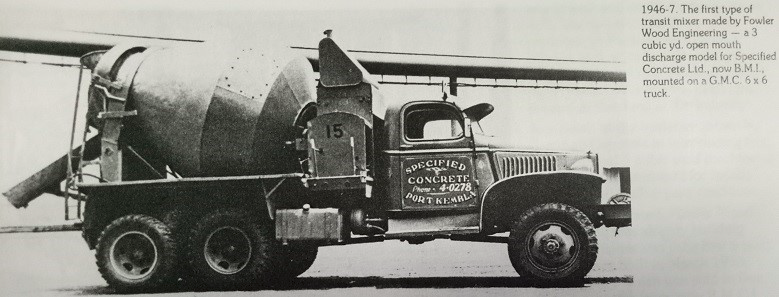

The next manufacturer on the scene in 1946 was Fowler Wood Engineer-ing (later Fowlerex). Fowler Wood built 3 and 4 yard machines similar to the Rex but without the hinged door. This technique was discontinued earlier in the U.S.A. in favour of the open mouth design. Components included a Vauxhall Petrol engine, A Maple Leaf truck gearbox, a Coote & Jorgenson reduction gear, extension shaft and pinion to a spur gear drive on the drum. In truth these machines often did more segregating than mixing and they were hopeless on low slump discharging.

Nearly all the machines used in Australia until 1952 were 3 to 4 cubic yard capacity, but in that year Certified Concrete obtained a licence from Challenge Cook of Los Angeles to build the Challenge 6 cubic yard machine. These were built by Moorfield Engineering of Sydney who turned out a total of 28 units within 5 years.

The Rex Motomixer. Note attempt to camouflage the inclined drum

The new 6 cu. yard machines were powered by a big 6 cylinder Chrysler engine, a custom built transmission, a special right angle reduction gear and a chain drive. These were mounted on Fodens and Leyland Hippos with a tandem drive, which was a vast improvement on the wartime G.M.C. 6 x 6 trucks, common around that time in the industry. The overall benefit was that these machines mixed quite well and could discharge down to 2” slump concrete.

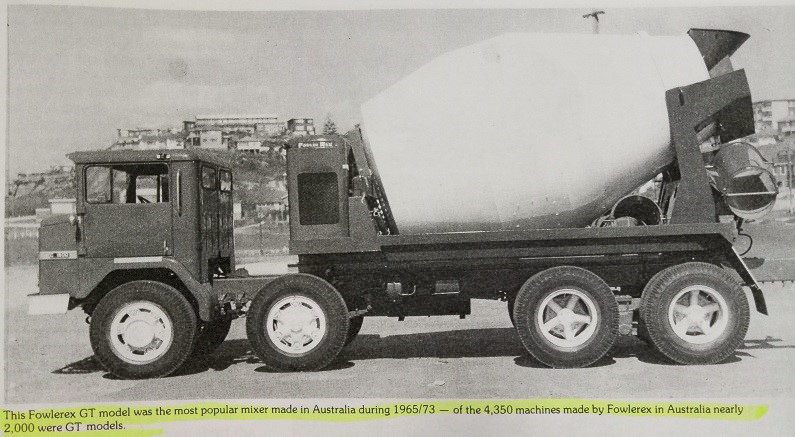

With Certified Concrete leading the way a demand soon developed for locally designed and built 6 yard machines. Fowler Wood Engineering then moved up from their 4 yard machines to broach the 6 yard market, building their first 6 yarder in March, 1955. Another manufacturer then entered the market – Marlak Engineering also started building 4 yard machines in late 1954. They built their first 6/7 yard machine in late 1955.

With Fowler Wood and Marlak being by now fairly well established, these two companies began to lead the field in both development design and market share. Both undertook a close, consultative working relationship with their clients in the pre-mixed concrete in-dustry. This led both manufacturers on a steep learning curve of the industry’s needs and importantly it also fostered the adoption of ideas and improvements, which originated in the field.

In this regard, it is fair to say that the present day Transit Mixer with all its efficiency and refinements is a product which has evolved as a result of long manufacturing experience, innovation and close liaison with the concrete industry.

Australian Innovations

- First in the world to achieve the efficient handling of low slump concrete

- World first in widening the mouth of the drum for fast charging & discharging

- Led the world in mixing concrete uniformly throughout the load and to comply with strict mixing efficiency tests

- First in the world to use Transit Mixers as Central Mixers on major civil constructions works—dams, tunnels, airports that required high specification concrete

Project Demands in Australia to a large degree drove the development of Transit mixing efficiency, which until the commencement of the great Snowy Mountains Hydro-Electric Scheme had not made much progress. The Snowy Mountains Authority adopted mixer efficiency testing procedures specified by the U.S. Bureau of Reclamation and although these tests were basically designed for large station-ary or tilting mixers, the Authority applied the procedures to Truck Mixers used on the tunnels and dams at the Snowy site.

Read the complete story covered in Issue 2 and all Issues in this History of the Transit Mixer in Australia at

https://www.cescoaustralia.com/latest-news/

* Pictures and Excerpts edited & sourced from: 1/ The Australian Truck Mixer – Its Origin and Development, published by NRMCA (National Ready Mixed Concrete Association of Australasia).